Top Maintenance Tips for Keeping Your Generator Set Running Smoothly

Jul 13,2025

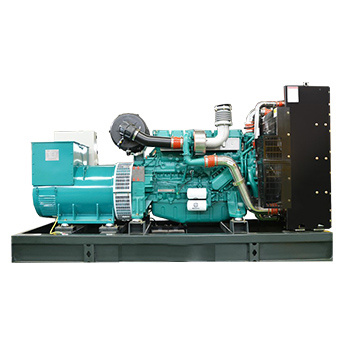

Top Maintenance Tips for Keeping Your Generator Set Running Smoothly Generators are essential for providing backup power in various situations, whether for homes, businesses, or industrial applications. Proper maintenance of your generator set not only ensures its longevity but also guarantees that it operates efficiently when you need it most. In this article, we will delve into detailed maintena

Top Maintenance Tips for Keeping Your Generator Set Running Smoothly

Generators are essential for providing backup power in various situations, whether for homes, businesses, or industrial applications. Proper maintenance of your generator set not only ensures its longevity but also guarantees that it operates efficiently when you need it most. In this article, we will delve into detailed maintenance practices that will help you keep your generator set running smoothly.

Understanding Your Generator Set

Before diving into specific maintenance tips, it’s crucial to understand what a generator set comprises and how it functions. A typical generator set consists of the engine, alternator, cooling system, fuel system, and control panel. Each component plays a vital role in the overall functionality of the generator, and regular maintenance can prevent breakdowns.

Key Components of a Generator Set

- **Engine**: The heart of the generator that converts fuel into mechanical energy.

- **Alternator**: Converts mechanical energy into electrical energy.

- **Cooling System**: Maintains optimal operating temperatures for the engine.

- **Fuel System**: Delivers fuel to the engine to create power.

- **Control Panel**: Provides the interface for monitoring and controlling the generator.

Essential Maintenance Tips for Your Generator Set

Maintaining your generator set involves several key practices that ensure its reliability and efficiency. Below are some top tips.

1. Regularly Check and Change the Oil

One of the most critical aspects of generator maintenance is oil management. The engine oil lubricates moving parts, reducing friction and preventing wear.

- **Frequency of Oil Changes**: Change the oil according to the manufacturer’s recommendations, typically every 100-150 hours of operation or at least once a year.

- **Use the Right Oil**: Always use high-quality oil that meets the engine’s specifications.

How to Change the Oil

1. Turn off the generator and let it cool.

2. Remove the oil drain plug and let the old oil drain into a container.

3. Replace the drain plug and fill the engine with fresh oil.

4. Check the oil level using the dipstick to ensure it is at the proper level.

2. Inspect and Replace Filters Regularly

Filters play a crucial role in the performance of your generator set by ensuring that clean air and fuel enter the engine.

- **Air Filter**: Inspect and clean or replace the air filter every 25 hours of operation or as needed.

- **Fuel Filter**: Check the fuel filter regularly and replace it according to the manufacturer’s guidelines to prevent clogs.

Steps to Clean or Replace Filters

1. Open the generator’s access panel.

2. Remove the old filter (air or fuel) carefully.

3. Clean or replace it with a new filter as per the specifications.

4. Close the access panel securely.

3. Keep the Cooling System in Check

A well-functioning cooling system is vital for preventing overheating.

- **Check Coolant Levels**: Regularly check the coolant reservoir and top it up with the appropriate coolant.

- **Inspect Radiator Hoses**: Look for signs of wear and replace damaged hoses to avoid leaks.

How to Maintain the Cooling System

1. Inspect the coolant level before and after operating the generator.

2. Clean the radiator fins to ensure proper airflow.

3. Ensure that the coolant is free from contaminants by draining and replacing it periodically.

4. Fuel System Maintenance

The fuel system is crucial for the efficient operation of your generator set. Contaminated fuel can lead to performance issues.

- **Use Fresh Fuel**: Always use high-quality and fresh fuel. Avoid using fuel that has been stored for more than six months.

- **Add Fuel Stabilizer**: If your generator will sit unused for extended periods, consider adding a fuel stabilizer to prevent degradation.

Steps for Fuel System Care

1. Drain old fuel from the tank if the generator isn’t used for a while.

2. Clean the fuel tank and lines regularly to prevent sediment build-up.

3. Replace fuel filters as needed.

5. Battery Maintenance

Maintaining the battery is essential for ensuring your generator starts easily.

- **Regularly Inspect Connections**: Check for corrosion and clean the battery terminals.

- **Test Battery Voltage**: Use a multimeter to check the voltage regularly.

How to Maintain Your Generator Battery

1. Clean battery terminals with a mixture of baking soda and water.

2. Ensure the battery is charged, especially before expected power outages.

3. Replace the battery according to manufacturer recommendations, usually every 3-5 years.

6. Routine Testing and Load Bank Testing

Regular testing of your generator ensures that it functions correctly when needed.

- **Run the Generator Monthly**: Start the generator monthly and let it run for at least 30 minutes under a load.

- **Conduct Load Bank Testing**: Perform load bank testing annually to ensure that the generator can handle its rated output.

Steps for Running a Load Bank Test

1. Connect a load bank to the generator.

2. Gradually apply the load to the generator.

3. Monitor the performance and check for any anomalies.

7. Keeping the Generator Clean

A clean generator not only looks good but also helps prevent overheating and other issues.

- **Remove Debris**: Clear away leaves, dirt, and debris from around the generator.

- **Wash Exterior**: Use a damp cloth to wipe the exterior surfaces to prevent rust and corrosion.

Steps for Cleaning Your Generator

1. Disconnect power before cleaning.

2. Use a soft brush to remove dirt and debris.

3. Rinse with water and allow to dry completely.

8. Monitor Performance and Listen for Unusual Noises

Pay attention to how your generator operates. Unusual sounds can indicate a problem that needs addressing.

- **Common Sounds to Watch For**: Grinding, knocking, or excessive vibration can signal issues with the engine or mounting.

- **Keep Records**: Maintain a log of any unusual sounds and when they occur for troubleshooting purposes.

FAQs About Generator Maintenance

1. How often should I perform maintenance on my generator?

**Routine maintenance should be performed every 100-150 hours of operation, at least once a year, or according to the manufacturer’s guidelines.**

2. Can I use my generator in the rain?

**While many generators are weather-resistant, it is best to use them in a dry environment to avoid electrical hazards. Consider using a generator tent or shelter.**

3. What type of oil should I use for my generator?

**Use high-quality oil that meets the specifications outlined in your generator's owner’s manual. Synthetic oils are often recommended for better performance.**

4. Is it necessary to run the generator under load?

**Yes, running the generator under load is essential to ensure that it operates correctly and to prevent issues like carbon build-up.**

5. What should I do if my generator won’t start?

**Check the fuel levels, battery connections, and ensure that the oil is at the appropriate level. If problems persist, consult a professional technician.**

Conclusion

By following these **maintenance tips**, you can significantly enhance the performance and longevity of your generator set. Regular checks and proactive care are vital to ensuring that your generator operates smoothly, especially during critical times. Remember to consult your **owner’s manual** for specific maintenance guidelines tailored to your generator model. With diligent care, your generator will be ready to provide reliable power whenever you need it, giving you peace of mind and security.

Related news