Efficient Generator Use Guide: Essential Maintenance and Operation Tips for Beginners

Jun 13,2025

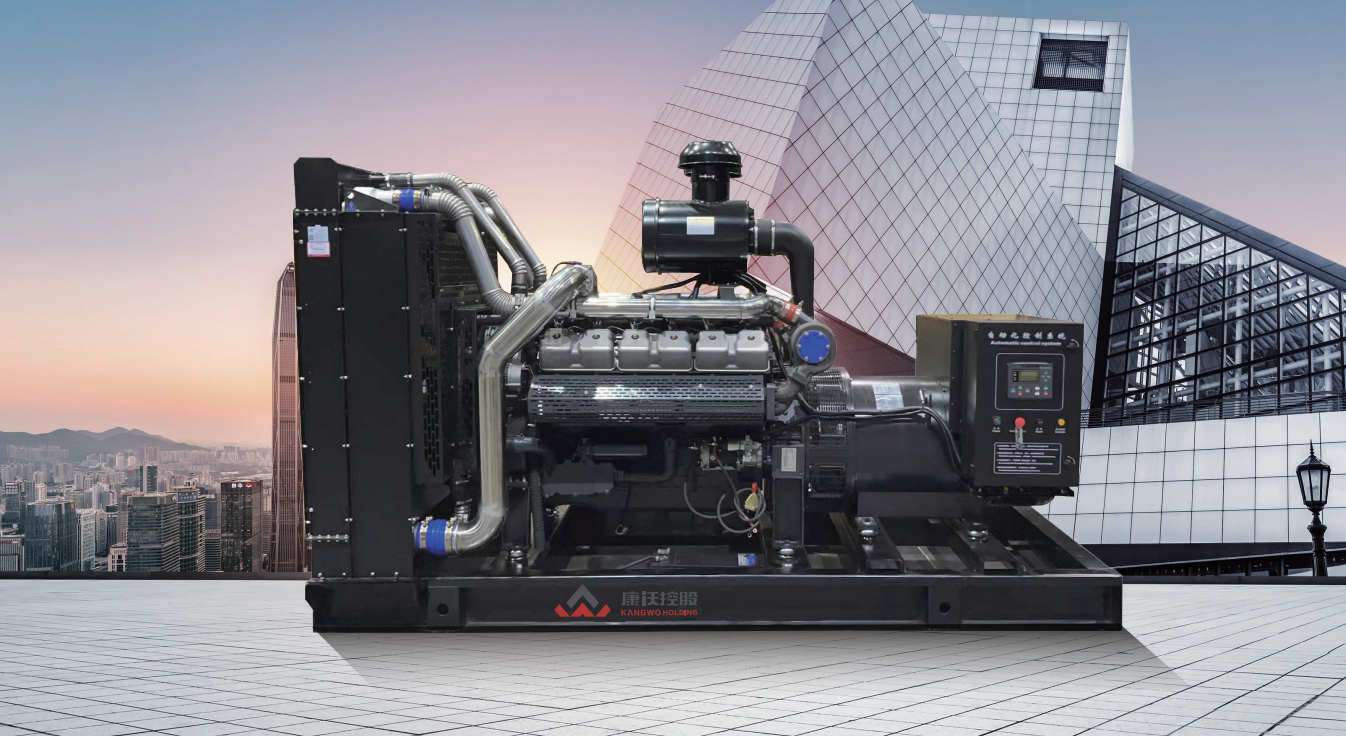

Diesel generators, through technologies such as electronically controlled direct injection, common rail, turbocharging, and intercooling, have significantly improved upon the shortcomings of traditional diesel generators. Their advantages in energy efficiency and reduced carbon dioxide emissions make them an irreplaceable "green power generation equipment" among all thermal power generation devices, including gasoline engines. So, what are the guidelines for using a diesel generator? What are the operational standards?

Diesel generators through electronic control direct injection, common rail, turbocharging and intercooling technology, significantly improve the problems of traditional diesel generators.At the same time, the advantages of diesel generators in energy saving and reducing carbon dioxide emissions make it an irreplaceable "green power generation equipment" among all thermal power generation equipment, including gasoline engines.So what are the guidelines for using diesel generators?What are the guidelines?

I. New Diesel Generator User Manual

1. For the first 50 hours of operation of a new diesel generator, it is recommended to keep the load below 80% of the rated power and strictly follow the manufacturer's break-in requirements to optimize the engine's long-term reliability and operating efficiency.

2. For diesel generators used in construction machinery, during the first 50 hours of operation, they should run at a partial load (recommended 50%~80% of rated power). Avoid prolonged idling or sudden load increases to ensure proper engine break-in.

3. Perform daily maintenance and servicing according to specifications. After using new equipment, check the oil pressure gauge, temperature gauge, warning lights, and other instruments to ensure they are functioning properly.

4. Add lubricant to the oil pan if it is not already filled; if the cooling system is already filled with coolant, check the coolant's performance. If it does not meet the requirements, drain it and add coolant that meets the standards.

1,For the first 50 hours of operation, the new diesel generator should be operated at no more than 80% of its rated load capacity.

2,For diesel generators used in construction machinery, they should operate at partial load (recommended 50%~80% of rated power) during the first 50 hours of operation. Prolonged idling or sudden load increases should be avoided to ensure proper engine break-in.

3,according to the standard requirements for daily maintenance, after the use of new equipment need to check the oil pressure gauge, temperature gauge, warning light and other instruments to ensure its normal operation.

4,the oil pan without lubricating oil needs to add lubricant in accordance with the regulations;

If the cooling system is already filled with coolant, the performance of the coolant must be checked, and if it does not meet the requirements, it should be discharged and the coolant that meets the standard should be added again.

II. Starting the Diesel Generator

1. Disconnect the load from the diesel generator.

2. Turn the start button to start the diesel generator. (To prevent damage to the starter and protect the battery, each startup should not exceed 30 seconds, and there should be at least a 2-minute interval between consecutive startups).

3. The oil pressure gauge reading must be displayed within 15 seconds after starting.

4. After a cold start, gradually increase the speed of the diesel generator to ensure adequate lubrication of the bearings and maintain stable oil pressure.

5. Allow the generator to idle for 3 to 5 minutes before applying a load.

1. 1, Disconnect the load from the diesel generator.

2, please Turn the start button to start the diesel generator.To prevent damage to the starter and protect the battery, the duration of each startup must not exceed 30 seconds, and the interval between two consecutive starts must be at least 2 minutes.

3, the oil pressure gauge reading must be displayed within 15 seconds after starting.

4, after the cold start of the diesel generator, the speed should be gradually increased to ensure that the bearing is fully lubricated and maintain the stability of the oil pressure.

5, After idling for 3 to 5 minutes, load and run again.

Previous: