Constituent materials of a diesel generator set

Jul 02,2025

Diesel generator sets provided by Shengqi Technology are small power generation devices powered by internal combustion engines. When there is a shortage of electricity, diesel generator sets become particularly important. As a self-contained power station and AC emergency power supply equipment, diesel generator sets are increasingly widely used in various fields.

Diesel generator sets are small power generation equipment powered by internal combustion engines. They are particularly important when there is a power shortage. As a self-contained power station AC emergency power supply equipment, diesel generator sets are increasingly widely used in various fields. During the procurement of diesel generator sets for various projects, we have learned that many owners do not understand why the prices of diesel generator sets of the same brand or even the same power can vary greatly. Therefore, we have made a brief analysis of the brand relationship, price composition, and other factors affecting the price of diesel generator sets in the following text. Let's learn about it together today.

I. Introduction to Diesel Generator Sets:

(1) Classification of Diesel Generator Sets:

There are many types of diesel generator sets, mainly classified in the following eight ways:

1. Classified by engine fuel: diesel generator sets and composite fuel generator sets.

2. Classified by speed: high-speed, medium-speed, and low-speed diesel generator sets.

3. Classified by usage conditions: land-based, marine, trailer-mounted, and vehicle-mounted diesel generator sets. Land-based generator sets include mobile and stationary types. Land-based units can be further divided into four types: ordinary, automated, low-noise, and low-noise automated.

4. Classified by generator output voltage and frequency: AC generator sets and DC generator sets. AC generator sets include medium-frequency 50Hz and power frequency 60Hz. The rated voltage of 50Hz power frequency small and medium-sized generator sets is generally 400V, and the rated voltage of large generators is generally 630-1050V.

5. Classified by the excitation method of the synchronous generator: rotating AC exciter and static exciter.

6. Classified by use: regular units, standby units, and emergency units.

7. Classified by control and operation method: on-site operation generator sets, compartment operation generator sets, and automated generator sets 。

8. Classified by automation function: basic diesel generator sets, automatic start diesel generator sets, and microcomputer automatic control diesel generator sets.

(2) Uses of Diesel Generator Sets:

A diesel generator is a small power generation device that uses diesel fuel and a diesel engine as the prime mover to drive a generator to generate electricity. Although diesel generator sets have lower power, they are widely used in mines, railways, outdoor construction sites, road traffic maintenance, and factories, enterprises, and hospitals as backup or temporary power sources due to their small size, flexibility, portability, complete accessories, and ease of operation and maintenance. When purchasing, it is important to ensure that the selected diesel generator set meets relevant standards and to choose it based on factors such as the purpose and operating environment. Since diesel generator sets can be used for regular, standby, and emergency purposes, different uses have different requirements for diesel generator sets.

(3) Composition of Diesel Generator Sets:

Diesel generator sets consist of a base, diesel engine, base tank, generator set (i.e., alternator), controller (which controls and protects the unit), radiator (air-cooled: fan; water-cooled: water tank), and soundproof box.

Figure: Engine

Figure: Engine

Figure: Controller

Figure: Controller

Figure: Soundproof Generator Set

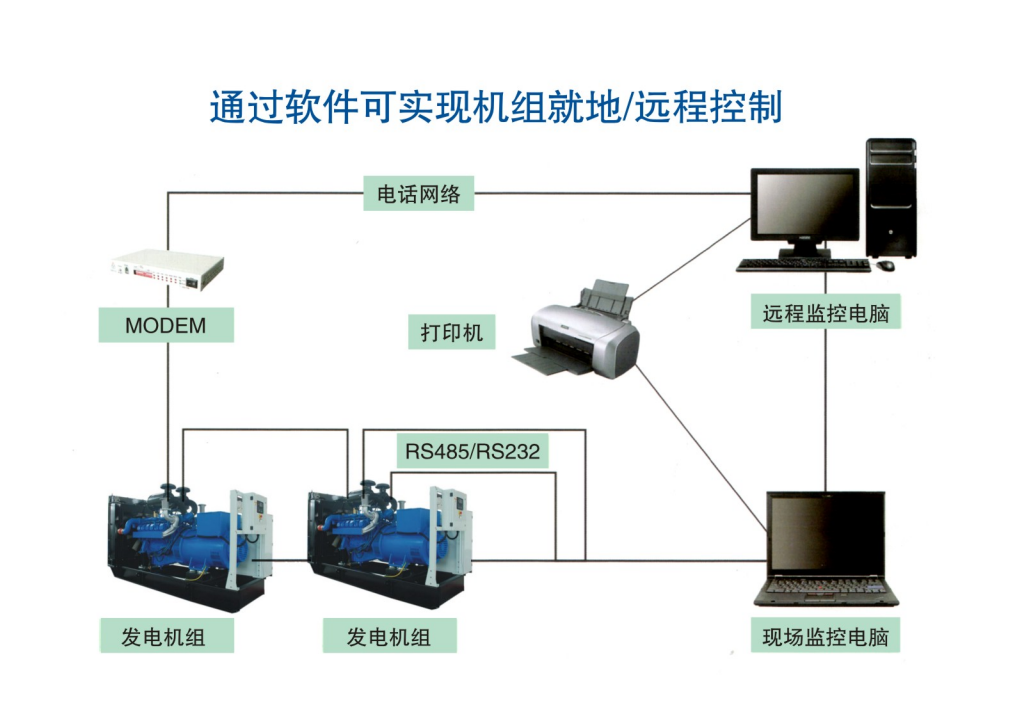

Figure: Control System

(4) Principle of Diesel Generator Sets:

The diesel engine drives the generator to rotate, converting the energy of the diesel fuel into electrical energy. In the diesel engine cylinder, clean air filtered by the air filter is fully mixed with the high-pressure atomized diesel fuel sprayed by the injector. Under the compression of the upward movement of the piston, the volume decreases, and the temperature rapidly increases, reaching the ignition point of the diesel fuel. The diesel fuel ignites, the mixture burns violently, and the volume expands rapidly, pushing the piston down, which is called "power stroke." Each cylinder works in a certain order, and the force acting on the piston is converted into a force that drives the crankshaft to rotate, thus driving the crankshaft to rotate. By installing a brushless synchronous AC generator coaxially with the diesel engine crankshaft, the rotation of the diesel engine can drive the rotor of the generator. Using the principle of "electromagnetic induction," the generator will output an induced electromotive force, and current can be generated through a closed load circuit. To obtain usable and stable power output, a series of diesel engine and generator control and protection devices and circuits are also needed.

(5) Performance Grades of Diesel Generator Sets:

National standard GB/T2820.1—1997 "Reciprocating Internal Combustion Engine Driven AC Generator Sets", Part 1: Applications, Ratings, and Performance, Clause 7 specifies four performance grades for diesel generator sets.

1. G1 performance requirements are applicable to connected loads that only require basic parameters such as voltage and frequency. General purposes, such as lighting and other simple electrical loads.

2. G2 requirements are applicable to loads that have the same requirements for voltage characteristics as public power systems. When the load changes, temporary but allowable voltage and frequency deviations are possible. Such as lighting systems, pumps, and fans.

3. G3 requirements are applicable to connected equipment with strict requirements for frequency, voltage, and waveform characteristics. Such as radio communication and thyristor rectifier controlled loads.

4. G4 requirements are applicable to loads with particularly strict requirements for frequency, voltage, and waveform characteristics. Such as data processing equipment or computer systems.

(6) How to Identify the Model of a Diesel Generator Set

In order to facilitate production management and use, the national standard has unified the method of model compilation for diesel generator sets. The arrangement of the unit model and the meaning of the symbols are as follows:

1. The rated power (KW) of the unit output is represented by numbers.

2. Types of unit output current: G—AC power frequency; P—AC medium frequency; S—AC dual frequency; Z—DC.

3. Unit type: F—Land-based; FC—Marine; Q—Automotive power station; T—Trailer.

4. Unit control characteristics: Missing indicates manual (standard type); Z—Automated; S—Low noise; SZ—Automated low noise.

5. Design serial number, represented by numbers.

6. Modification code, represented by numbers.

7. Environmental characteristics: Missing indicates standard type; TH—Tropical humid type.

Note: Some diesel generator set series models have different meanings from the above models, especially imported or joint venture diesel generator sets, which are determined by the generator set manufacturer itself.

II. Diesel Generator Set Installation Standards:

(1) Ventilation:

1. Air intake: According to the capacity of the diesel generator set, the manufacturer provides the required size of the air intake, and the buyer should reserve the air intake during construction.

2. Exhaust port: According to the capacity of the diesel generator set, the size of the exhaust port can be determined, and the buyer should reserve the exhaust port during construction.

(II). Exhaust:

Exhaust must be discharged directly outdoors through a properly designed exhaust system, which should be equipped with a random exhaust muffler. The outer end of the pipe should be cut at a 60-degree angle to the horizontal, or equipped with a rain or snow protection system.

(III). Foundation and Fixing:

According to the capacity of the diesel generator set, the unit provides the corresponding foundation dimensions to meet the load requirements during normal operation of the unit. The foundation is required to be a concrete floor. The entire generator is accurately installed with an alternator and engine using a rigid frame at the factory. Therefore, when installing this unit, it only needs to be fixed to a good foundation with high-quality expansion bolts.

III. Diesel Generator Set Price Composition:

Through our long-term exploration and data comparison, we have found that in the price composition of a diesel generator set, the engine generally accounts for about 80% of the total cost, and the generator, control system, and accessories account for about 20% of the total cost. At the same time, the "three major components" of the diesel generator set also have different selection and combination methods:

Complete set import: Diesel generator, engine, and control system all use the same imported brand.

Domestic assembly: Diesel generator, engine, and control system are purchased from different brands, and then assembled into a complete set by domestic manufacturers. However, the selection of different brands of "three major components" will also cause different price differences. For example: The generator uses imported or joint venture brands, the engine uses domestic brands such as Yuchai, Shanghai Diesel , Weichai, etc., and the control system uses imported or domestic brands.

(I). Price Composition:

In terms of detailed price composition, the engineering price of a diesel generator set generally includes the following items: 1. Diesel generator set cost; 2. Installation, transportation, and commissioning cost of the unit; 3. Exhaust gas treatment and obtaining a qualified monitoring report; 4. Noise reduction project and obtaining a qualified noise monitoring report (noise reduction includes unit noise reduction and room noise reduction); and sometimes, according to the owner's requirements, a fifth item: the cost of the flue pipe outside the room.

Example: Taking the joint venture brand Chongqing Cummins as a reference, the price of a 1200kw Chongqing Cummins generator set = 1.25 million for the unit (including 1 million for the engine, 200,000 for the generator, 40,000 for the controller, and 10,000 for the base) + 10,000 for unit installation, transportation, and commissioning + 40,000 for exhaust gas treatment + 40,000 for unit noise reduction + room noise reduction price + flue pipe price outside the room (the last two items require drawings or specific requirements to quote. If the owner requires room noise reduction, it includes the room ceiling and walls, and the price is calculated at 120 yuan/㎡).

(II). Analysis of Price Differences in the Three Major Components:

1. Engine:

Taking the commonly used brands "Mercedes-Benz", "Perkins", "Mitsubishi", "General Motors", and "Chongqing Cummins" as examples in the commonly used power range of 1200kw, the price of the "Mercedes-Benz" engine is slightly higher than the other four brands, while the prices of "Perkins", "Mitsubishi", "General Motors", and "Chongqing Cummins" engines are around 1 to 1.2 million yuan. The price of the "Mercedes-Benz" engine is around 1.3 million yuan. The prices of domestic first-tier brands such as "Yuchai", "Shanghai Diesel", "Weichai", and "Jichai" are 15%-30% lower than those of joint venture and imported brands. In terms of engine technology, because domestic engine technology started late, there is still a certain gap with joint venture and imported brands.

2. Generator:

Taking the commonly used brands "Shanghai Marathon", "Guangzhou Yangjiang Yingge", "Wuxi Stamford", "Wuxi Faraday", and "Fuzhou Leilisenma " as examples, the prices of generators for 1200kw diesel generator sets are all around 200,000 yuan, with little price difference.

3. Control System:

Due to the mature technology of generators and control systems, taking the commonly used brands "Zhongzhi", "Shenhai", and "Koman" as examples, the price differences between different brands are very small, and the highest price of a control system is also within 40,000 yuan.

(III). Price Differences of Diesel Generator Sets with Different Combinations:

Taking the commonly used 1200kw diesel generator set as an example: The price of a 1200kw complete set import = 1.5 times the price of a 1200kw engine (imported or joint venture) after the complete set is assembled = 2 times the price of a 1200kw domestic first-tier complete set after assembly (the lump-sum price of a 1200kw Chongqing Cummins is about 1.35 million)

Content comes from Zhencaishiliao official website. Please contact us to delete if there is any infringement.

Next: