African partners visit Saintkey Technology and Cornwall Holdings to purchase generator sets

Jul 29,2025

Accompanied by relevant personnel from Saint Qi Technology and Cornwall Holdings, partners first visited the factory showroom. The showroom detailed the development history of Cornwall Holdings, showcasing key stages from its inception to its gradual growth.

On July 25, 2025, African partners visited Shengqi Technology and Cornwall Holdings for an exchange visit.

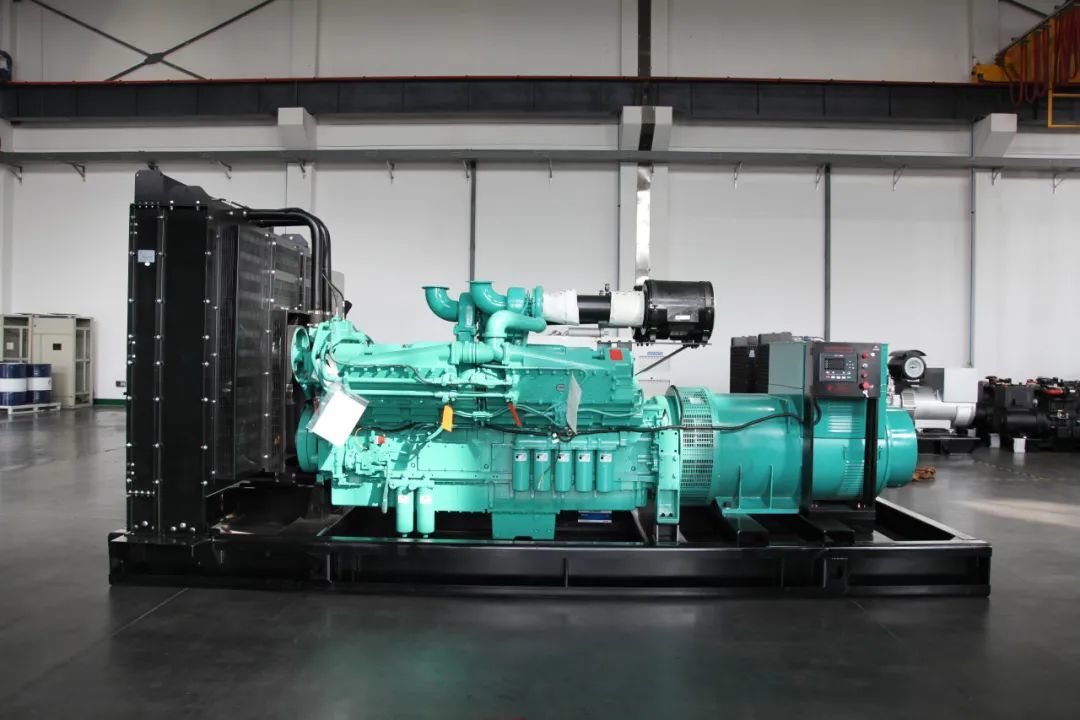

Accompanied by relevant personnel from Shengqi Technology and Cornwall Holdings, the partners first visited the factory showroom. The showroom detailed Cornwall Holdings' development history, showcasing key stages from its inception to its gradual growth. Staff introduced Cornwall Holdings' key development milestones and achievements in the power generation equipment field. Following this, a focus was placed on examining the various series of generator sets produced by Cornwall Holdings. Staff provided specific explanations of the power range, technical characteristics, core advantages, and applicable scenarios of different generator models, such as industrial backup power, infrastructure construction, and mobile power stations.

Power System: The brands and models of the diesel engines used, and their performance in terms of fuel efficiency, reliability, and low emissions were introduced.

Generator Core: The winding technology, insulation grade, protection grade, and stability of the voltage regulation system of the generator (alternator) were explained.

Control System: The functions of the intelligent control panel were demonstrated, including remote monitoring, automatic start/stop, fault diagnosis, and protection mechanisms (such as overload, short circuit, low oil pressure, and high water temperature protection).

Application Solutions: Using specific examples, the practical application effects of different specifications of generator sets in mining, factories, hospitals, data centers, construction sites, and power supply in remote areas were illustrated.

After the showroom visit, the partners went to the production workshop for a field inspection. Entering the workshop, they first observed the production area of the core engine components, including the processing of key components. Staff introduced aspects such as material selection and processing precision control. Subsequently, the clients visited the generator set assembly line, observing the assembly process of the unit from components to the complete machine, including the connection of the engine and generator, the installation of the control system, and the connection of pipelines. Workshop personnel explained the process requirements and quality control points during the assembly process. Finally, they visited the testing area before product completion, understanding the various performance tests that the generator sets must undergo before leaving the factory, such as load tests, continuous operation tests, and safety protection function verification. Throughout the workshop visit, they exchanged views with company personnel on production equipment, processes, and quality assurance systems.

After the showroom visit, the partners went to the production workshop for a field inspection. Entering the workshop, they first observed the production area of the core engine components, including the processing of key components. Staff introduced aspects such as material selection and processing precision control. Subsequently, the clients visited the generator set assembly line, observing the assembly process of the unit from components to the complete machine, including the connection of the engine and generator, the installation of the control system, and the connection of pipelines. Workshop personnel explained the process requirements and quality control points . Finally, they visited the testing area before product completion, understanding the various performance tests that the generator sets must undergo before leaving the factory, such as load tests, continuous operation tests, and safety protection function verification. Throughout the workshop visit, they exchanged views with company personnel on production equipment, processes, and quality assurance systems.