Maldives clients conduct in-depth visits to Saint Qi Technology and Cornwall Holdings, and the generator sets' strength gains international recognition

Aug 01,2025

Recently, a Maldivian client visited the Saintkey Technology and Cornwall Holdings production base to procure a highly reliable genset solution for its high-end hotel facilities. During the carefully arranged itinerary, the client comprehensively inspected the genset product display and the entire modern manufacturing process.

Recently, a Maldivian client visited the Saintkey Technology and Cornwall Holdings production base to procure high-reliability generator solutions for their high-end hotel facilities. During the carefully arranged itinerary, the client comprehensively inspected the generator product display and the entire modern manufacturing process.

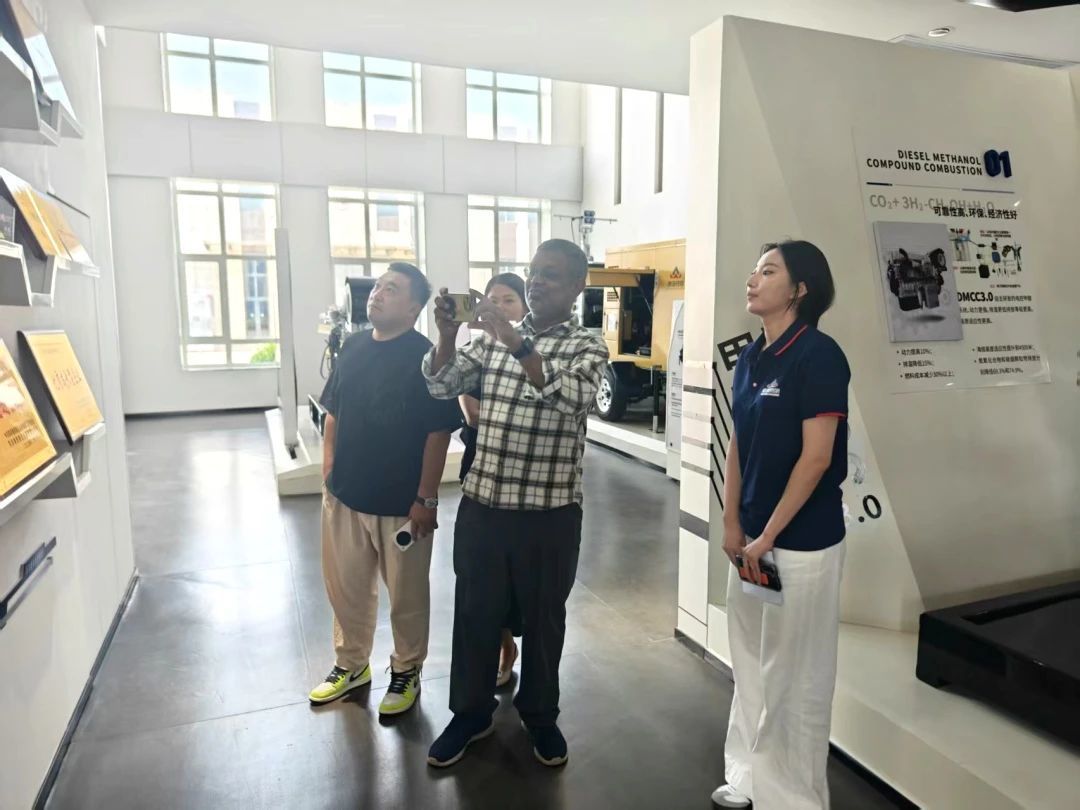

In the professional and bright generator showroom, Saintkey Technology and Cornwall Holdings technicians detailed the technical highlights and application scenarios of several main generator sets to the client. The client was particularly concerned about the stable performance of the units in harsh environments, especially inquiring about special protection and heat dissipation optimization solutions in the high-temperature, high-humidity, and high-salt environments of tropical islands. Combining past island project experience, the technicians meticulously answered core technical details such as material anti-corrosion processes and customized heat dissipation systems.

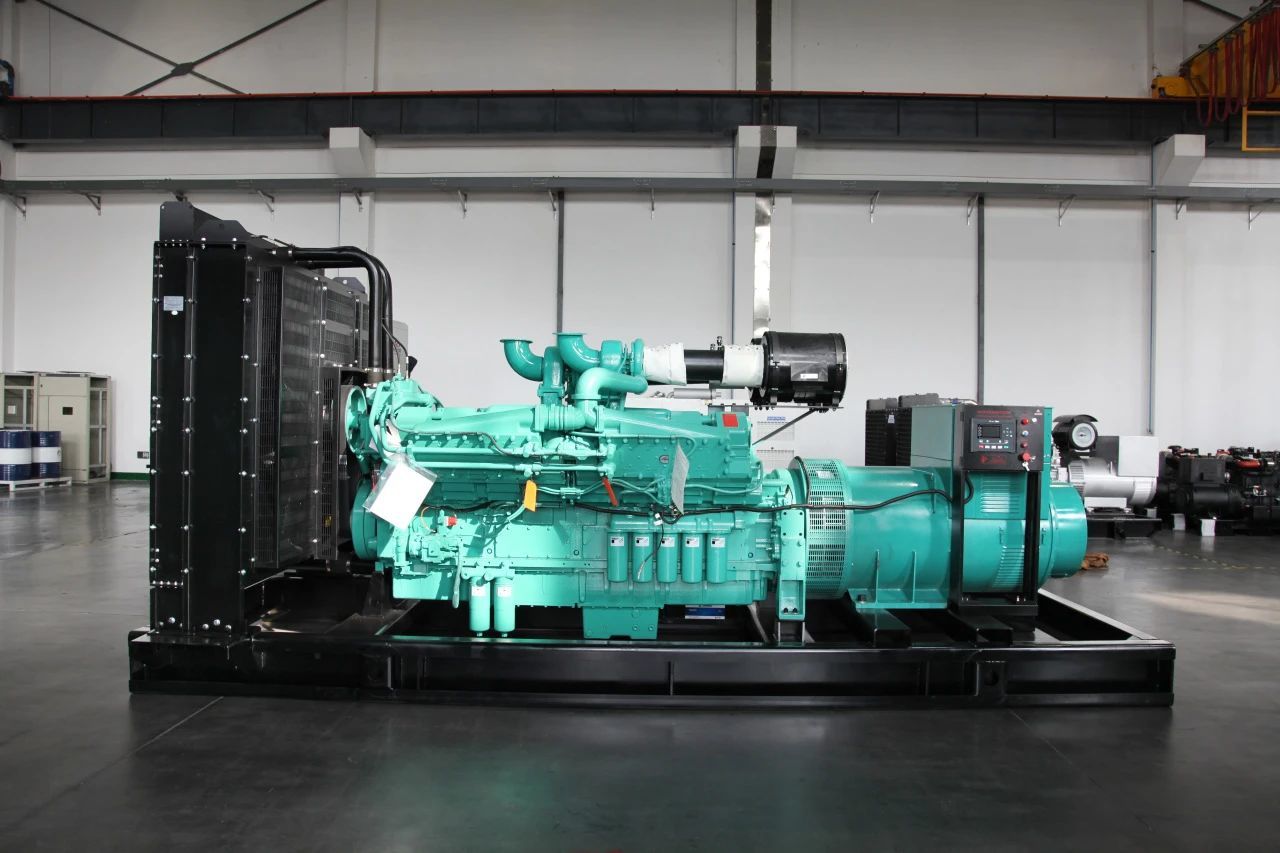

Subsequently, the client went deep into the Cornwall Holdings production workshop. From the automated processing of precision parts to the rigorous assembly and layer-by-layer quality inspection processes, the client witnessed firsthand the process of the unit's creation from raw materials to finished products. They particularly appreciated the quality control process of key components and the multiple rounds of load testing before the unit's factory delivery. Beside the assembly line, the client engaged in in-depth discussions with engineers on practical issues such as generator noise reduction design, intelligent control systems, and localized maintenance support.

Subsequently, the client went deep into the Cornwall Holdings production workshop. From the automated processing of precision parts to the rigorous assembly and layer-by-layer quality inspection processes, the client witnessed firsthand the process of the unit's creation from raw materials to finished products. They particularly appreciated the quality control process of key components and the multiple rounds of load testing before the unit's factory delivery. Beside the assembly line, the client engaged in in-depth discussions with engineers on practical issues such as generator noise reduction design, intelligent control systems, and localized maintenance support.